PROCESS REFRIGERATION

Coolant Management Modules

Food & Beverage Lines

Process chillers

Load Profiling

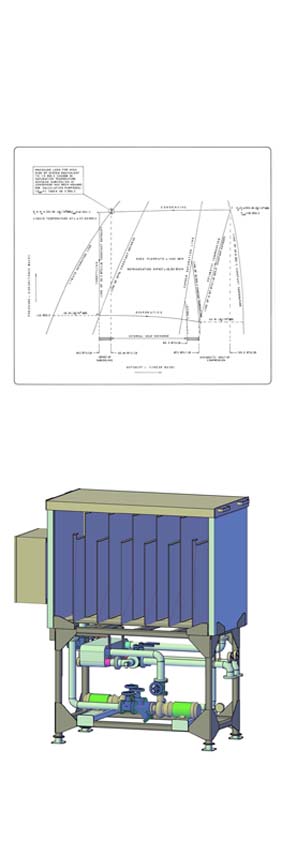

Coldstore heat loads tend to be self-damping, while production processes are more likely to be dynamic in character, requiring agile response by the host system. Real-time demands in batch- or batch-continuous operations can vary widely, whilst those of hybrid applications (such as ground freezing) change gradually and predictably in one direction.

While a small fridge plant might respond readily to varying loads, it becomes desirable to reconcile capacity and demand more economically as heat flows increase. For example, the 85 kW air-cooled chiller in the photo serves an application cycling to several times its rating. By smoothing-out peaks and troughs between process load and chiller rating, push-pull flow across one of our coolant management modules matches refrigeration capacity against prevailing conditions. It presents the chiller with a relatively constant load near to its design point, so that the machine runs at best available efficiency at a steady - but much smaller – loading.

Alternative Fridge Plant Concepts

Process refrigeration is remarkable for its variety and ingenuity. For instance, the Air Cycle - used primarily in aircraft - takes compressed air from the propulsion engines, which is then discharged into the cabin via an expansion turbine for pressurisation and cooling purposes. Croll Reynolds’ two-stage vacuum fridge plant works on the steam jet cycle, with water as its working fluid.

In absorption refrigeration, mechanical compression is supplanted by a mass transfer operation. This process – traditionally with ammonia as working fluid- is used in small domestic and recreational refrigerators, while a packaged Lithium Bromide absorption fridge plant can run to over 3500 kW capacity. A further development entails adsorption - then desorption - of the working fluid onto a surface (methanol onto carbon, for example). Although both types use direct heat as the driving force, the absorption cycle is currently preferred for process chillers, while adsorption machines are favoured for trigeneration (cooling-heating-power) schemes for reasons of safety, reliability and reduced maintenance.

Examples of Process Refrigeration Projects

Transport refrigeration coils for Searle Refrigeration; Ice-making equipment design for Sea Ice Limited

Cryogenic Process Refrigeration for Kraft Foods; Absorption chiller plant evaluation for Home Brewery

Fridge plant upgrade for North Quay Cold Stores;Ground Source HVACR plant for University of Wales

Evaporator liquid distributors for the Design Council; Coolant management modules for Axis Bottling