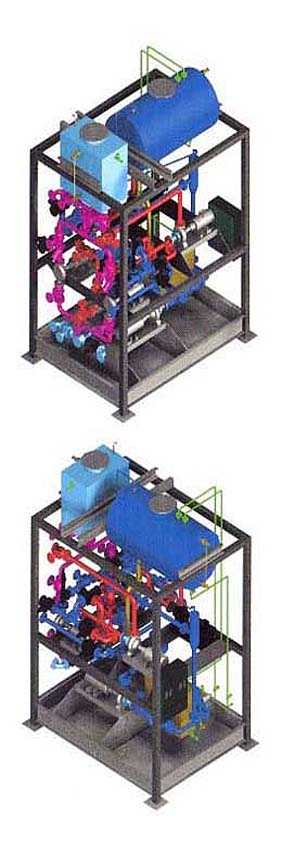

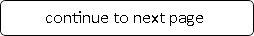

BALANCE OF PLANT MODULES

Dove Thermal Engineering designs and builds BoP skids for chemical process sidestreams and environmental control plant, power generation and boiler plant services equipment, and for marine propulsion and ancillaries. We provide professional engineering services in all thermally-related topics.

Origins

The modular Balance of Plant concept emerged in the marine industries during the early 1960s, with companies such as Rolls-Royce, Serck Heat Transfer and Coventry Radiator pioneering drop-in electromechanical BoP packages. Marinized BoP skid mount generating units - along with fuel oil conditioning, lub oil cooling and filtration balance of plant skids - could be installed during fit-out, and exchanged from the dockwall on a single tide. This anticipated the automated engine room, and present day ship management practices. More recently, similar packaging concepts are being used to provide central services for site-based environmental control plant.

Advantages

Dove Thermal has been designing and building Balance of Plant modules for over thirty years. The advantages of bringing together all services necessary for a core application are of particular value in the pre-engineering of complex systems, when site access is in some way restricted, or when installations are to be made at remote worksites. We hold the DTI's award for Excellence in Design Engineering and Project Management and were engineering design consultants to the MAS and DAS for their duration. Production plant, process acceleration & product design are core activities.