SOLID STATE THERMAL APPLIANCES

and

IMMERSION COOLERS

Peltier-Seebeck Thermoelectrics

Solid State Heating & Cooling

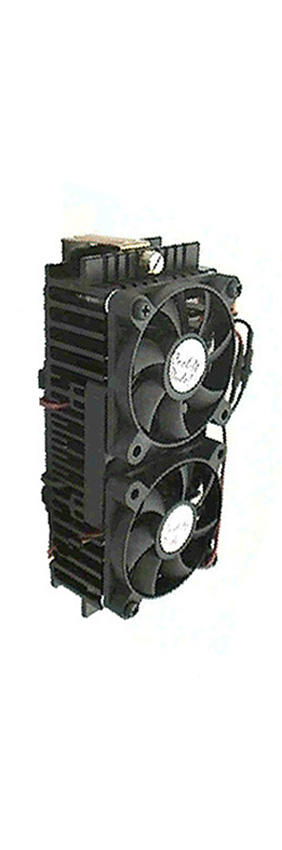

Peltier Appliances

Description

Voltage potential across two dissimilar semi-conductors creates a temperature difference between them caused by electron diffusion, which is properly called the Peltier-Seebeck Effect. Arrays of semi-conducting pairs are typically manufactured as wafer-thick modules in sizes of up to around 60mm square and 6mm deep. Immersion coolers and other large solid state appliances employ chips containing up to 287 semi-conducting junctions.

Performance Perspectives

Coefficient of Performance – CoP - generally varies between 0.3 and 0.7 according to circumstance. This is the ratio of cooling effect against power supplied. Although in contrast, thermodynamic cycles might return CoP of around 3.0 across corresponding temperature gradients, Peltier appliances enable processes that could not otherwise be contemplated. They provide practical cooling solutions for compact high value applications such as avionic and research equipment, descrete devices subject to variable accelerations, and operations requiring precise control of energy flow (such as calibrated immersion coolers & heaters).

Electrical power may be obtained by heating one side of an array and cooling the other, and some Peltier-Seebeck modules are specifically designed for that purpose. Efficiencies are low, with generation capacity seldom exceeding 4W. Peltier appliances have a finite longevity - usually of up to ten or twelve years. Even where CoP is not of particular importance, cost factors in heating mode compare unfavourably with other methods of heat-to-power conversion.

Other Applications

Circuit boards and other small, confined spaces are natural environments for Peltier-Seebeck devices. Cost, CoP, power consumption, and temperature differentials act as constraints on domestic and personal Peltier appliances. Whilst expectations must be tempered with realism where heavy cooling loads meet high ambients, Dove Thermal has produced several successful solid state appliances on clients' behalf. These include various immersion coolers, a table-top wine cooler, a cooling jug, and a chill box with integral freezer compartment.