DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

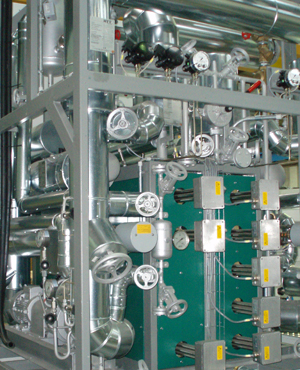

Steam System Design

Saturated steam is a precision isothermal medium for process heating vessels employed in manufacturing operations, works utilities and site resources. It enables high rates of energy transference over long distances without need of mechanical intervention. Steam may be generated from any type of fuel, in any quantities, and within any chosen continuum of rate, temperature and pressure. It may be superheated beyond its natural saturation temperature to provide local high energy supplies for power, chemical and production operations. Steam system design is well-supported by a knowledgeable and ethical supplier basis, providing education, advice and off-site management services for site services and manufacturing applications.

Thermal Fluid Heating

While Dove Thermal began life as steam engineers, we have designed and built several skid-mounted and installed process heating systems incorporating our shell-and-tube electric HTF heaters and thermal fluid calandria for synthetic fluids and hot oil systems. At temperatures above 340 degrees or so, vapour pressures of even the most tolerant synthetic fluids tend to rise above atmospheric, so that - without careful management - the design and operating conditions of thermal fluid heating systems can affect their useful working life. Their replacement cost should be offset against the water treatment and attendance requirements of steam plant, given saturation pressures of steam at temperatures above 200 deg.C might appear to mark this as a working limit for general use. Although thermal fluid heating and hot oil heating systems can be worked either side of atmospheric pressure, pressurised installations allowing operation above their normal saturation temperatures are more complex than for steam.

No thermodynamic pressure is induced during the heating of a thermal fluid if its vapour pressure remains below atmospheric, and engineering costs are much-reduced if systems are to operate only under gravity head. Generally speaking, electric calorifiers for thermal fluid and hot oil heating fall within SEP classification of the PED and are not CE marked. As they do not require ventilation for combustion air supply, electrically-fired and steam-heated calorifiers are suitable for installation in airconditioned spaces and clean room environments. Direct firing, resistance or induction heating may be employed where liquid phase process heating systems are impracticable.

Special Heat Exchangers and Heat Transfer Equipment

Most proprietary equipment comprises either plate type or shell-and-tube heat exchangers. While process installations or OEM plant & machinery might typically incorporate selections from standardized ranges of heat transfer equipment, gas turbines, road vehicles and mass-produced appliances generally employ special heat exchangers of compact, lightweight construction designed to meet host equipment configurations. Vessels might be heated by dimpled jackets, thermal fluid calandria or immersed coils. Precision machined castings, laser-cut profiles, low-volume pressings are likely to be mechanical prerequisites for custom applications, while the thermal process design of shell and tube heat exchangers calls for considerable knowledge and experience.

Heating Plant Designers

Dove Thermal designs, builds and commissions process heating vessels equipped with HTF calandria, jacketed or externally-recirculated batch heating vessels for heating and tempering duty in chemical and food production processes. We have designed and built various types of biothermal energy plant for biomass conditioning and space heating applications.

Please also refer to our specialist page at Liquid Phase Heating & Hot Oil Heating Plant

Examples of Dove Thermal Process Heating Systems and Equipment:

Trent 900 environmental test support systems for Rolls-Royce Aerospace

Steam system design for Eversmart Express, Stowlin, Fibracan et al.

Variable concentration batch heating vessels for Banner Chemicals

Vapour phase Dowtherm A Heating Plant for Glaxo Smith Kline

HTF Calandria and Special Heat Exchangers for Tate & Lyle

Gas-fired baking oven heating module for Spooner-Vicars

Production line induction heating for Hughes Christensen

Biothermal energy plant for Vantage Waste Processing

Thermal oxidiser recuperator for Stein Atkinson Stordy

Test plant thermal fluid calandria for Cullum Detuners

Buffer storage process heating systems for HS Butyl

Process heating vessels for Tate & Lyle Sugars

Heating plant designers for Alcan Aluminium UK

Thermal fluid heating system for Tiflex Limited

Shell-and-tube heat exchangers for IAC

Dove Thermal Engineering Limited, Uttoxeter, ST14 8QX

Telephone: 01889 569933