DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

Process Tank & Storage Vessel Upgrades

Please contact Dove Thermal should you need to enhance the process performance of a tank or vessel – by improving heating, cooling or mixing arrangements for instance. We can undertake all the necessary calculations for determining performance of planned retrofits and their process effect, and modify the equipment on-or-off site as appropriate.

Process Vessels & Steam Calandria

We design and engineer shell-type research and custom autoclaves working under vacuum or positive pressure, heated either electrically, with steam or by HTF media. Specifically, we have capability and experience in designing and building custom autoclaves – along with the heat transfer and manufacturing processes undertaken in them. Process vessels may be jacketed or quilted, fitted with coils, steam calandria, or arranged for recirculation of their contents through primary heating or cooling equipment. Primary fluid systems for chemical reactors may operate isothermally (as with saturated steam or refrigerant) or be set up for sensible operation (with thermal fluid calandria, for example); whilst endo- or exothermic reactions may be tempered accurately to follow optimum process conditions with respect to time. We provide steam calandria for new or existing process vessels, tanks and equipment, fully supported by thermal design calculations and mechanical specifications.

Dove Thermal Engineering has more than thirty years experience in the process and mechanical design of heat and mass transfer equipment, including absorption columns, gas quenching vessels and cooling tower packings.

Productions

Processes for HTF calandria tempered operations.

Custom autoclaves for laboratory and field applications.

Mathematical modelling, pipe stress and related services.

Columns and towers for heat and mass transfer operations.

Oil and thermal fluid calandria for non-aqueous environments

Retrofit dimpled quilting available in stainless or non ferrous materials.

Chemical reactors with immersion coils for integration with new or existing plant.

Heat transmission by jackets, coils, steam calandria, injection or external recirculation.

Jacketed vessel design for batch, continuous and hybrid processes for heating & cooling.

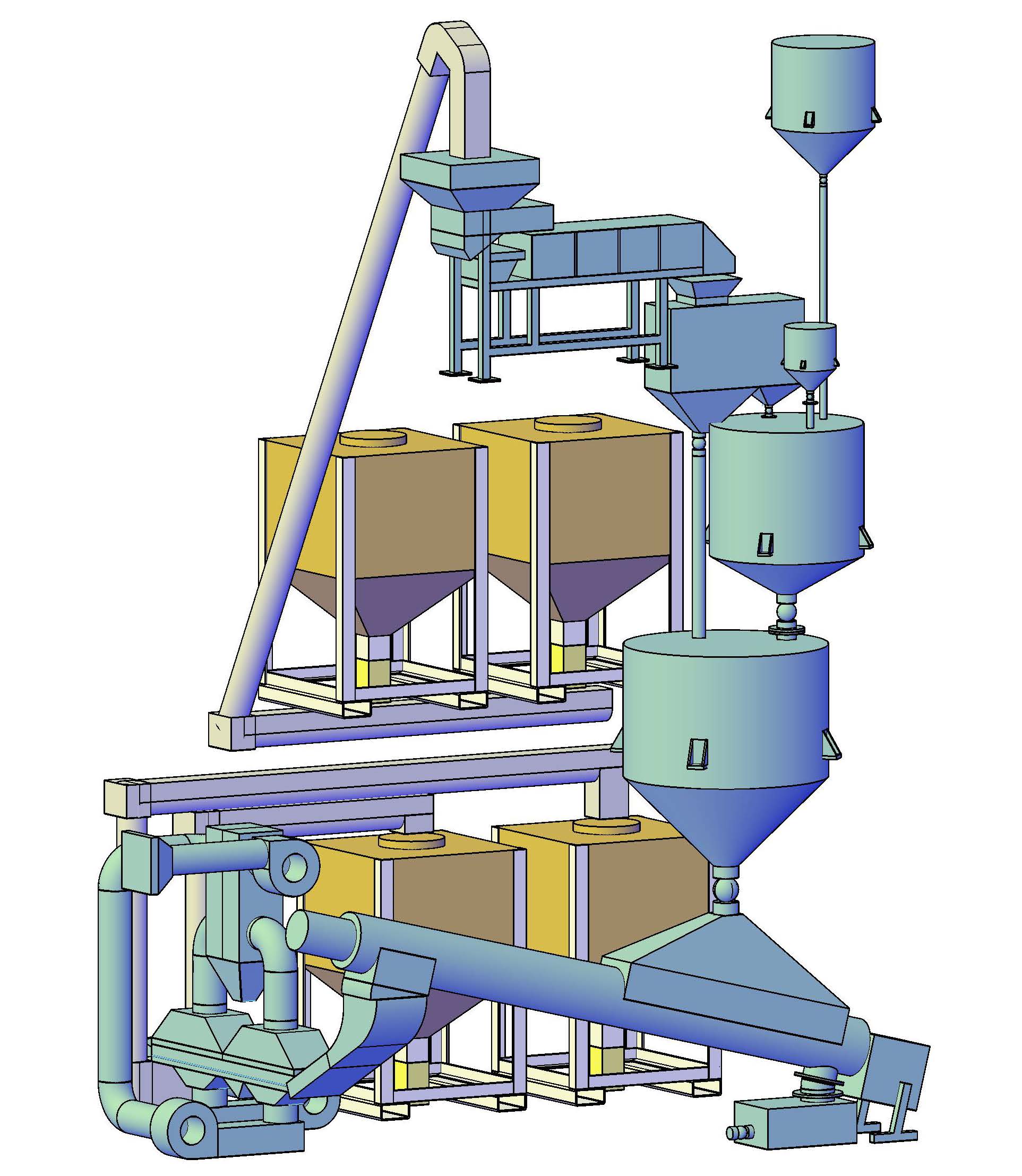

Design Drawings

GAs solid models of process vessels with PIDs & stress isometrics

Fully-integrated design & production output from Bricsys software

Materials and Standards

TIG, MIG, SMAW, FCAW and MMA weld procedures

Pressure vessel codings to PD 5500, ASME VIII Div.1, etc.

Polished, brushed, galvanized, powder-coated and epoxy finishes.

Capacity and Workscope

Fuel test rig tempering vessel HTF calandria for Cullum Detuners

Autoclave design & mathematical modelling for Design Council

Thermodynamic Steam Explosion Valve for McCains Group

Boiling pan steam calandria for Tate & Lyle Special Sugars

Chemical reactors and processes for Banner Chemicals

Large roped tube process condensers for Tate & Lyle

High vacuum furnace systems for Torvac Processing

Pressurised Dowtherm heating plant for DuPont

Custom autoclaves for Freeland Horticulture

Dove Thermal Engineering Limited, Uttoxeter, ST14 8QX

Telephone: 01889 569933