DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

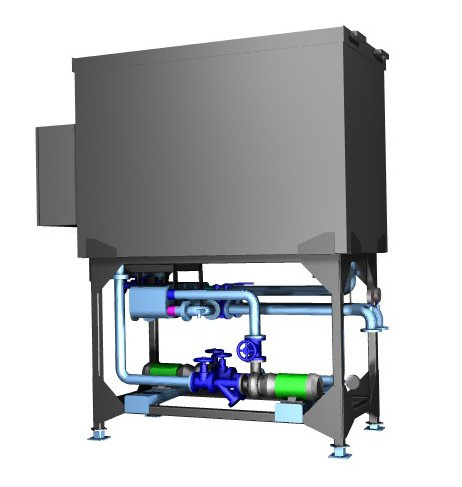

Coolant Management Tanks

While small fridge plants respond readily to varying loads, it becomes desirable to reconcile capacity and demand more economically as heat flows increase. For example, the 85 kW air-cooled chiller in the photo serves an application cycling to several times its rating. By smoothing-out peaks and troughs between process load and chiller rating, push-pull flow across one of our coolant management tanks (shown below) matches refrigeration capacity against prevailing conditions. Dove Thermal's unique Regenerative Cooling Process presents the chiller with a relatively constant load near to its design point, so that the machine runs at best available efficiency at a steady - but much smaller – loading.

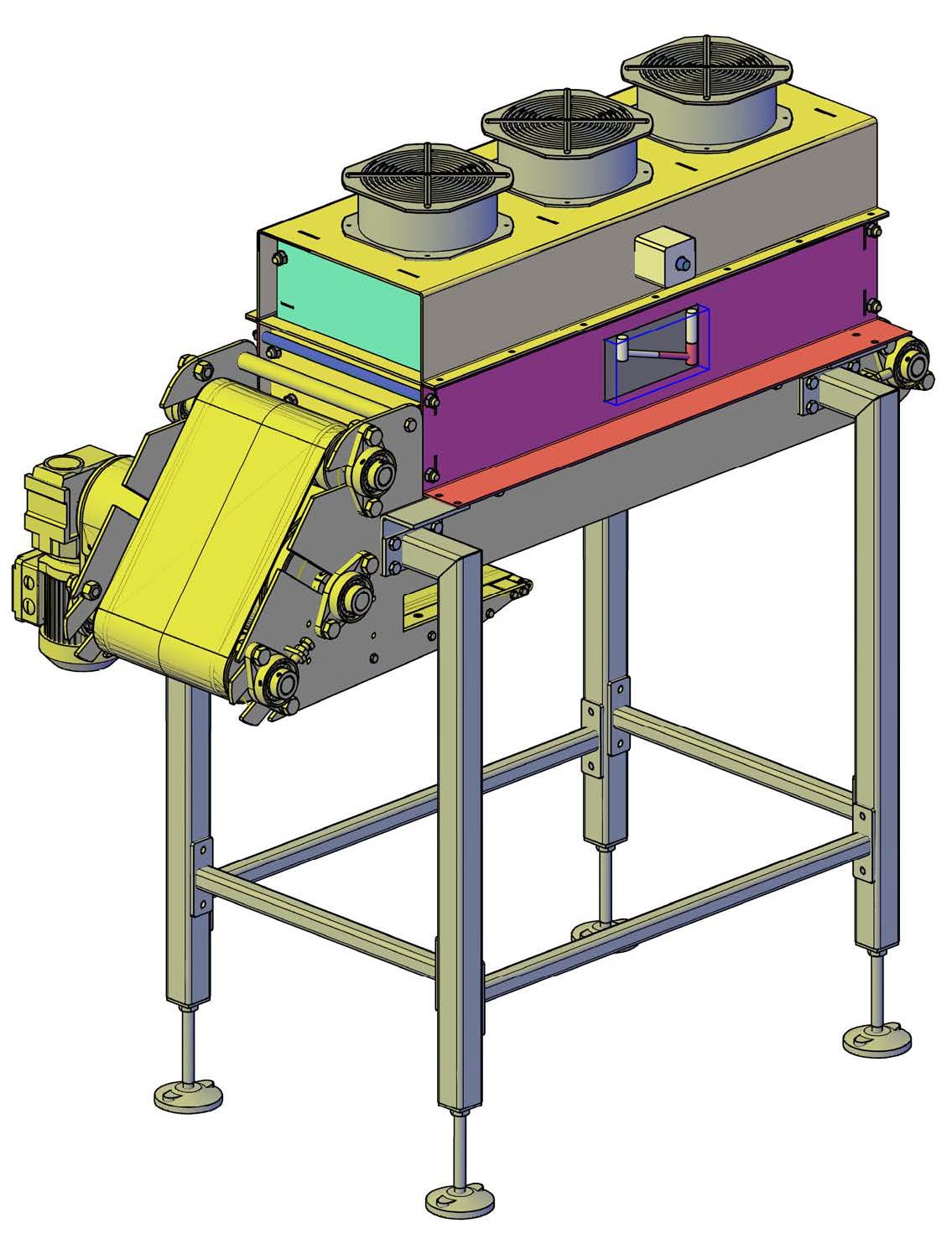

Food Processing Tunnels

Dove Thermal's long experience with conveyor-line drying and air quenching tunnels extends from fried food products manufacture and chocolate enrobing through to engine cylinder block casting and sintered component production. Tunnel sections may be used for raw materials preparation, intermediate stage conditioning and product finishing, and wherever a process is to be contained. A drying tunnel may be fitted either with local bridge-mounted solvent handling and recovery equipment, or ducted to remote systems.

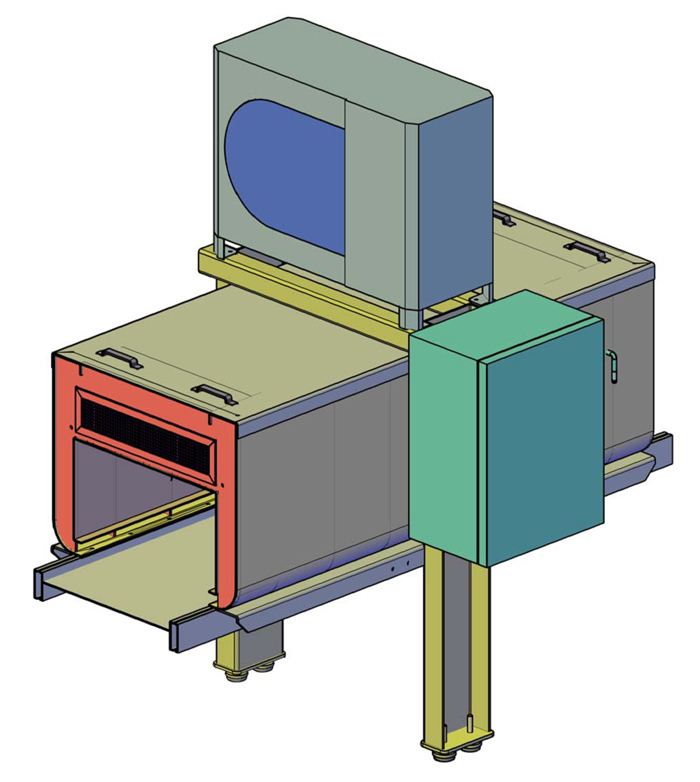

Process Chiller Plant Design

The isometric below shows a chilled-air cooling tunnel section with integral entry and exit air curtains to contain the cooled and dehumidified tunnel air mass. These suppress the humid transfer that would otherwise be caused by the vapour pressure gradient between conditioned and ambient air, maintaining a stable and controllable micro-climate in the tunnel section. The solid model is for a proprietary bridge-mounted condensing set, and continuous internal slot nozzles for edge-on air delivery. Assemblies may also be configured for vertical impingement of cooling air onto the conveyor band, or combined drying and cooling for product conditioning.

Product Conditioning Tunnels

We have developed unique self-jigging fabrication methods for the construction of HVACR assemblies, which have been successfully extended to the manufacture of sections for product conditioning tunnels and the construction of air quench tunnels. They exploit recent advances in CIM laser profiling and sheet metal forming to produce precision-built equipment with near off-the-shelf availability.

Examples of Process Refrigeration Projects:

Cryogenic Process Refrigeration for Kraft Foods

Coolant management modules for Axis Bottling

Fridge plant upgrade for North Quay Cold Stores

Ice-making equipment design for Sea Ice Limited

Ground Source HVACR plant for University of Wales

Transport refrigeration coils for Searle Refrigeration

Evaporator liquid distributors for the Design Council

Absorption chiller plant evaluation for Home Brewery

Dove Thermal Products

Steam-Heated Calorifiers;

Thermal Oil Heaters

Shell-and-Tube Heat Exchangers;

HTF Heaters

Thermal Fluid Heaters;

HTF-Heated Calandria

Packaged Quench Plants;

Air Handling Units

Packaged Plant Skid Mounts

Balance-of-Plant Modules

Dove Thermal Services

Forensic Engineering;

HVRAC Engineering

Thermal Design & Product Development

Consult-Design-Construct Services

Thermal Engineering Consultancy

Process Plant & Process Design

Thermal Fluid Heating Systems

Environmental Systems Design

Dove Thermal Engineering Limited, P.O.Box 5, Uttoxeter, ST14 8QX

Telephone: 01889 569933