DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

Steam v Thermal Fluid Heating

At temperatures above 340 degrees or so, vapour pressures of even the most tolerant synthetic fluids tend to rise above atmospheric, so that - without careful management - the design and operating conditions of process heating systems can affect their useful working life. It may be reflected that steam at 300 deg.C raises a head just slightly below 85 bar(g). That said, a thermal fluid can also be operated above saturation pressure, given precautions to inhibit oxidation of the working medium, either by cooling the system expansion tank or nitrogen-blanketing the liquid surface.

Fluid Heating Options

Dove Thermal are expert in the application, design and manufacture of electrically-fired HTF heaters and heating systems. Electric firing offers very precise heat input and control, and location of heat source adjacent to application on the factory floor. Coil-type boilers fired by gas or fuel oil are best located away from production spaces, as may be required by statutory regulations and/or insurance considerations. There are instances where steam heating of heat transfer fluids offer a convenient and economical solution to local application requirements. As they do not require ventilation for combustion air supply, electrically-fired and steam-heated calorifiers are suitable for installation in airconditioned spaces and clean room environments.

Thermal Fluid Plant Parameters

HTF heating and hot oil systems can be worked either side of atmospheric pressure, although pressurised installations allowing operation above their normal saturation temperatures are more complex than for steam - partly through need to inhibit oxidation of the working medium. Even so, a synthetic HTF or thermal oil heater can run at 300 deg.C under normal pressure, whilst saturation pressure for dry steam at that temperature is around 85 barg. No thermodynamic pressure is induced where the fluid vapour pressure remains below atmospheric, and engineering costs are much-reduced if systems are to operate only under gravity head. Generally speaking, electric calorifiers for synthetic fluid and hot oil heating would fall within SEP classification of the PED and are not CE marked.

Thermal Fluid Heaters

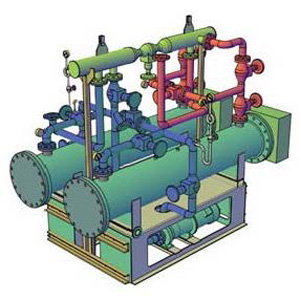

Dove Thermal Engineering has built fired- and unfired HTF heaters for Therminol and Dowtherm synthetic fluids and Shell Thermia hot oil systems. We have successfully worked Solutia T66 at temperatures to 340 deg.C under atmospheric pressure - as for our Klieverik thermo-bonding calendering machine installation (see Gallery page). Our shell-and-tube pattern electric calorifiers have been configured both as skid-mounted and installed systems. The isometric shows a modularized pair of electric HTF heaters packaged as drop-in replacements for an earlier gas-fired plant.

Pipework Design

Although carbon steel is to be preferred for hot oil heating and thermal fluid plant operations, we have designed, stressed, built and commissioned pressurised systems in other materials by request. Thermally-induced movement in carbon steel is lower, and properties retention much superior. Our method for pre-tensioning pipe support systems enables quick and accurate installation.

Experience

As mentioned elsewhere in these pages, Dove Thermal Engineering is a peer group management company providing engineering consultancy, plant-building, and millwrighting services. We have been designing and building heat transfer equipment for over thirty years, and hold the DTI's award for Excellence in Design Engineering and Project Management. Dove Thermal were specialist engineering design consultants to the Manufacturing and Design Advisory Services over their duration, with production plant, process design and product innovation as our core activities.

Typical Capacity and Workscope:

Liquid phase heating plant for International Automotive Components

Electric thermal oil heater installation for Sigma Technologies

Pressurized HTF systems rectification for Midland Oil Refinery

Multiple HPHW, LPHW and hot oil heating installations

Thermal fluid heating plant for Tiflex Limited

HFT heating plant & equipment for Flint Ink

Dove Thermal Engineering Limited, Uttoxeter, ST14 8QX

Telephone: 01889 569933